Enhancing Quality with Automated Visual Inspection: A Game-Changer

Automated visual inspection is revolutionizing quality control by using cameras, sensors, and artificial intelligence to detect defects in products or processes with unparalleled precision. Unlike manual inspections, which are prone to human error and fatigue, automated visual inspection ensures consistency, speed, and accuracy, making it indispensable in industries like manufacturing, pharmaceuticals, and food production. By integrating advanced imaging and machine learning, these systems identify anomalies in real-time, boosting efficiency and reducing costs. This guide explores their components, applications, and transformative potential.

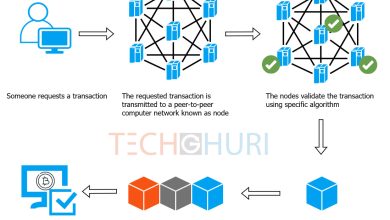

The Mechanics of Automated Visual Inspection

Automated visual inspection systems combine hardware and software to scrutinize objects for flaws. High-resolution cameras, often 2D or 3D, capture detailed images, while specialized lighting, like LED arrays, enhances contrast for better analysis. Machine learning algorithms, such as convolutional neural networks (CNNs), process these images to detect defects like cracks, misalignments, or contamination. The systems integrate with production lines, providing real-time feedback to halt faulty processes. This technology ensures compliance with stringent standards, like ISO 9001, while logging data for traceability.

Key Components and Technologies

The backbone of automated visual inspection includes advanced cameras capable of capturing high-speed or hyperspectral images for material analysis. Processing units, often embedded with AI chips, handle complex computations. Software platforms, built on frameworks like OpenCV, enable pattern recognition and anomaly detection. Integration with programmable logic controllers (PLCs) ensures seamless operation within automated workflows. These components work together to deliver inspections at speeds unattainable by human operators, often processing thousands of items per minute.

Implementing Automated Inspection Systems

Deploying automated visual inspection begins with assessing your needs, such as the types of defects to detect and required inspection speed. Select vendors like Cognex or Keyence, known for robust vision systems tailored to specific industries. Training the system involves feeding it sample images of good and defective products to build accurate models. Calibration ensures precision, while validation tests measure false positive rates to fine-tune performance. Integration with existing machinery requires collaboration with engineers to minimize downtime during setup.

Benefits Across Industries

The advantages of automated visual inspection are profound. In manufacturing, it ensures zero-defect production, reducing recalls by up to 50% in some cases. The pharmaceutical industry uses it to verify pill counts or detect packaging errors, ensuring patient safety. In food production, it identifies contaminants, like foreign objects, maintaining compliance with health regulations. Logistics benefits from automated package scanning, improving accuracy in sorting. These systems deliver cost savings by reducing labor and waste while enhancing product reliability.

Industry-Specific Applications

Automated visual inspection shines in diverse sectors. In automotive manufacturing, it checks weld quality or paint finishes, ensuring safety and aesthetics. Electronics producers use it to inspect solder joints on circuit boards, catching defects invisible to the naked eye. Textile manufacturers detect fabric flaws, like tears or stains, ensuring quality. Aerospace firms rely on it for surface inspections, identifying microscopic cracks that could compromise safety. Each application underscores the technology’s versatility and precision.

Overcoming Implementation Challenges

High upfront costs can be a barrier, but the return on investment often materializes within 1-2 years through reduced labor and error costs. Environmental factors, like dust or vibration, may affect camera performance, requiring protective enclosures or stabilization. Training models for diverse products demands large, varied datasets to avoid overfitting. Regular maintenance, including lens cleaning and software updates, ensures long-term reliability. Addressing these challenges upfront ensures smooth operation.

Real-World Success Stories

Ford implemented automated visual inspection in its factories to detect paint defects, reducing recalls and saving millions annually. A pharmaceutical company used it to inspect vial packaging, cutting error rates by 70%. These cases highlight the importance of pilot testing and vendor partnerships to tailor systems to specific needs, delivering measurable improvements in quality and efficiency.

Future Trends in Automated Inspection

By 2025, automated visual inspection is evolving with Industry 4.0. Integration with IoT enables predictive maintenance, reducing downtime. 5G connectivity supports remote monitoring, allowing real-time oversight across global facilities. Sustainable designs, using energy-efficient components, align with green manufacturing goals. Advances in quantum computing promise faster image processing, while collaborative robots (cobots) enhance system flexibility. These trends position automated inspection as a cornerstone of smart factories.

Optimizing Your Inspection System

To maximize ROI, train operators to interpret system outputs and troubleshoot issues. Use analytics to identify production bottlenecks, refining processes. Partner with vendors for ongoing support and upgrades. Automated visual inspection transforms quality control, delivering precision and efficiency that redefine industry standards.